Myoelectric Soft Robotic Hand

September 2016 - May 2017

Final year project for my Mechanical Engineering Bachelor’s degree.

Our team built an anthropomorphic soft robotic hand with in mind the goal of creating safer, more affordable prosthetics.

Our main challenge was building a prototype the size of an adult human hand, with enough strength and speed to achieve everyday tasks, implementing a closed loop control to control the soft actuators bending angle.

My personal contributions to the project were mainly focused on:

Improving manufacturing techniques to reduce the soft actuators’ defects and fabrication time

Designing the soft actuators to replicate human finger motion, within the size and force output requirements of the project

Adding EMG input to the main control loop

My teammates also worked on strengthening by adding composites and flexible sheet metal implants and incorporating a flex sensor in the design to implement close loop control.

Our project is a recipient of the Disney- HKUST Grant for Technology and Well-Being

Manufacturing soft actuators

Our team, along with others in our lab, built soft actuators by casting silicone rubber in 3D printed PLA molds. As part of getting familiar with this fabrication process, I introduced several protocol changes to address inconsistent quality issues we were facing while controlling for the material properties: redesigning molds, adding a preprocessing step in a vacuum chamber and curing the casts at a controlled temperature. I verified the consistency of material properties throughout by running tensile tests on cast samples.

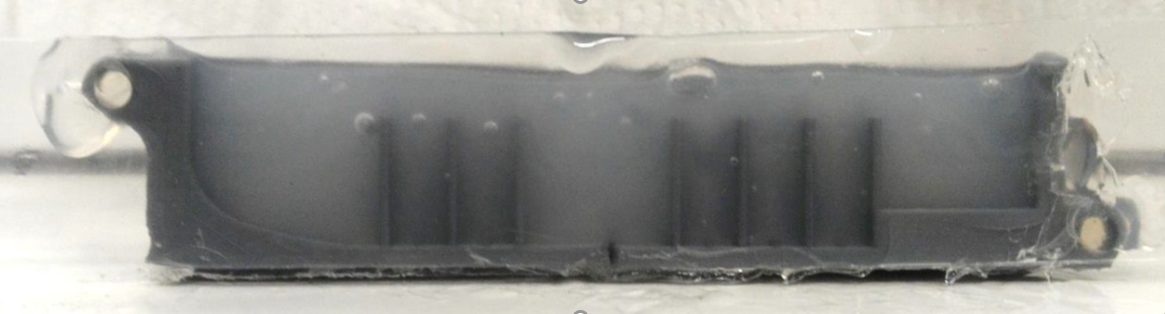

Splitting the mold in several parts reduced demolding failures and mold breakage

Pre-processing the silicon rubber in a vacuum chamber and controlling the curing at 40 deg helped us reduce defects due to bubbles, and standardise the curing process to reduce batch variability.

Designing soft actuators

My objective was to design soft actuators that would replicate a human finger flexion motion while maximizing their force output given size restrictions.

I first tested controlled parameters to determine how much different design parameters influenced the relationship between input pressure and force output (chamber dimension, number of chambers, chamber wall thickness, etc.) and optimize the overall design given my multiple constraints.

Test samples with controlled dimensions

Then went on designing the actuator in CAD, taking into account the results from the force tests, and estimating chamber inflation at the maximum rated pressure of 3 MPa: these estimates were used to design the hand’s 5 different fingers given human fingers DoF at each joint.

CAD models

Once the key design parameters were determined, adapting them to create the different fingers of a hand was straightforward: except for the pinky finger, for which chamber wall dimensions were too small for our fabrication methods.