Blood Screening Device

May - July 2019

When I was based in Xi’an, I helped a university research group automate a blood screening protocol based on a new sensing strip technology they developed in their lab.

Worked on the entire hardware and firmware design of a benchtop testing prototype.

Step 1: What the device needs to do

The research group I was working with developed a novel sensing paper strip that would change impedance when specific proteins bind to it. Being extremely cheap to produce, the group wanted to commercialize their test strips for use in preliminary blood screening in large healthcare facilities.

Protocol

deposit blood on sensing strip

incubate the strip at 37°C for two hours in an airtight chamber

measure impedance of the strip after incubation.

Step 2: Proof of concept

For the first iteration, I designed a custom board to test several features the benchtop device would need.

Main features:

ATSAMD21G MCU

Two alternative designs for Peltier drivers

DC-DC 5A Buck Converter

Impedance and Temperature measurement using an external ADC IC

Eagle CAD design of the custom board

In its first iteration, the buck converter had excess noise and ripple at the switching node. I had to modify it and rework the PCB to alleviate the problem

Reworking the PCB to debug the buck converter

Noise and ripple at the switching node

Step 3: Integrated prototype

After testing all the device’s functions independently with the first board, I moved on to designing the benchtop prototype. I worked on the mechanical and electronics design in tandem, to ensure the overall coherence of the assembly, then spent about a week perfecting firmware for the ATSAMD21G microcontroller on board.

The research team used this prototype to engage healthcare institutions for pilot tests and trials.

The device uses a polyimide film heater to heat a large aluminum slab and fans to maintain the strips’ temperature at 37°C. The aluminum slabs also acts as a sealing mechanism to keep the strips air tight.

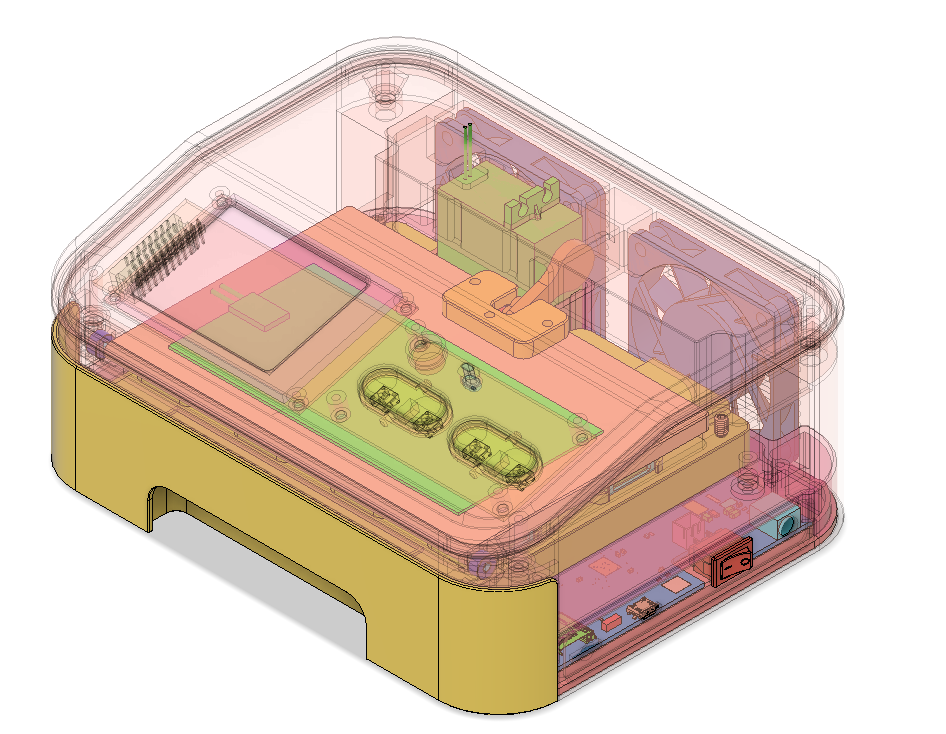

3D CAD of the benchtop prototype.

Inner view

The strips are encased into easy to handle chips with a basic resistor divider circuit and unique serial number IC to simplify testing.

Array of test chips

Test chip design, with strip shown in blue. Blood can be deposited on the strip through the opening.

Assembly of the prototype. Most parts are SLA printed, some were machined in ABS plastic and aluminum.

Test chips plugged into the device and ready for testing