Assembly line fatigue monitoring

September - October 2019

Repository: all versions PCB + code

A HAX Startup developing light passive exoskeleton supporting the arms and shoulders wanted to give their customer more insights on worker fatigue and task monitoring on overhead assembly lines

I developed a simple wearable they could strap on the exoskeleton to measure:

fatigue from repetitive movements or maintained posture

long term exposure to vibrations from tool use

exposure to noise

Step 1: Data gathering prototypes

To get an idea of what sort of data we would encounter using wearables for activity monitoring, I built a few sensor breakout boards to use with a Raspberry Pi Zero W, with which I could do basic preliminary data gathering and analysis using python. I used the data gathered with these prototypes to narrow down the final sensor selection (body coupled 9 axes IMU and microphone) and choose the general signal processing approach to use in the next iteration.

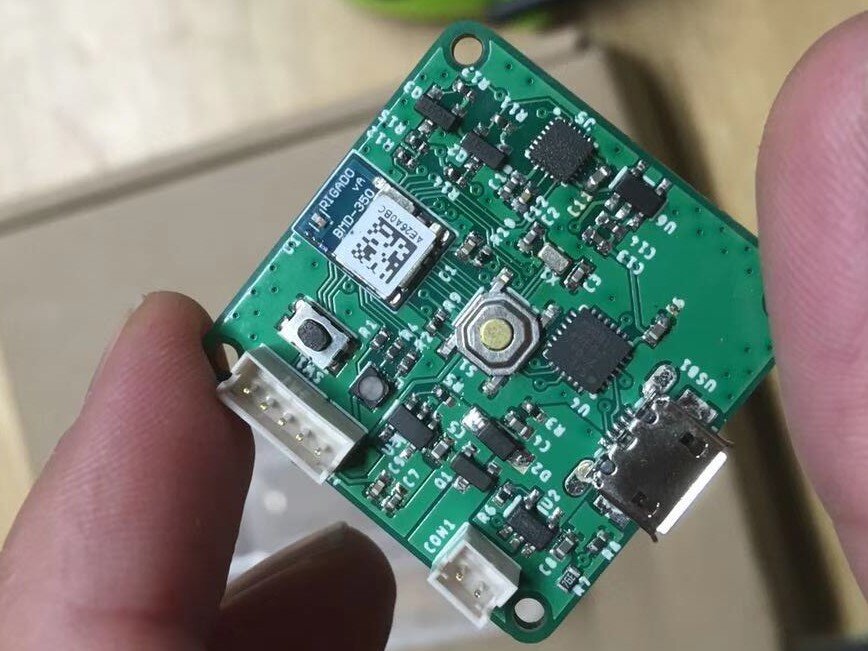

Step 2: Embedded wearable sensor node

After the sensor approach was validated I focused on making a lower power, smaller module to be deployed onsite for a longer study. The sensor node is based on an NRF52832 and can log/and stream data over BLE.